Ship ahoy in architecture: a building like a ship's hull with advanced smoke extraction

The 122 metre long and 14 metre high building on the Oder island of Lastadie (Łasztownia) follows the slight curve of the quay, giving the architects additional design freedom. The side walls are positioned at different angles to each other, creating a different impression from every angle. Another characteristic feature is the elongated skylight, which is reminiscent of ship superstructures.

The winning design from 2011 was created by the architecture firm Płaskowicki & Partnerzy from Warsaw. Since then, the original idea of a simple museum in Poland's seventh largest city with more than 400,000 inhabitants has developed into much more, namely an interactive building.

Originally intended to look like a rust-coloured new ship in a shipyard, the designers changed their minds and chose orange, red and yellow panels reminiscent of shipping containers. They wrapped these rectangles in a mains supply that softens the colour tones somewhat. The general contractor Erbud bathes the façade in different coloured light using 400 LEDs - the effect is breathtaking.

While the Maritime Science Centre resembles a ship's hull from the outside, the exhibition area is an open space with the cross section of an inverted cone. Bartosz Słodkowski knows only too well how challenging it is to work with this. He heads up the design department at the Szczecin-based automation company Przedsiębiorstwo Usług Specjalistycznych MVB:

"Designing an effective smoke extraction system for such an unusual volume was a major challenge. We succeeded with the help of a series of skylight domes for smoke extraction and windows in the façade and entrance door for ventilation." The building is divided into several smoke zones by stationary and retractable smoke protection curtains.

"This means that the control system has to process dozens of elements according to a complex control matrix", explains Słodkowski. "It determines how the system works depending on the detected source of the fire. Smoke extraction is ensured by several control units that are networked and synchronised with the BMS and HVAC systems."

Specific solutions were already required for LEED certification. Słodkowski cites automatic gravity ventilation with skylight domes, ventilation and vent windows for air exchange and temperature control as examples.

To lower the temperature in the morning and ensure a certain amount of air exchange, the operation of the smoke vent system in conjunction with the BMS and HVAC systems opens the skylight domes and some of the windows. The weather station determines the duration.

All in all, the built-in components for temperature control and air exchange save considerable energy costs.

"The system can also be activated manually to fan or regulate the temperature. Information from the HVAC automation system, the BMS system and the current weather situation help with the decision, depending on the number of building users. In the event of a threat, such as a sprayed toxic substance, the system can also be activated independently of the fire detector and alarm system."

The Science Centre, which together with the Maritime Museum covers more than 10,700 square metres, is named after Jerzy Stelmach (1954-2012), professor at the University of Szczecin, physicist and cosmologist, science author and creator of scientific exhibition concepts.

The extensive exhibitions will be spread over three levels. The permanent exhibition will feature interactive scientific and technical elements and more than 200 exhibits relating to life in and with the sea. The planetarium with 60 seats is planned as a special attraction. There will also be space for a conference room, three training rooms and workshops for modelling and boat building as well as chemistry, biology and mechatronics/physics rooms. A restaurant and a viewing platform will soon welcome visitors on the roof.

Such a huge and multifunctional attachment requires an efficient ventilation and smoke extraction system. D+H Polska was entrusted with this task - and brought the associated trades on board.

"This special and technically demanding building required an unconventional approach from the suppliers", says CEO Mariusz Ziemecki, summarising the challenges.

Modern technological thinking combined with a creative approach and smooth teamwork led to the desired success - without going over budget.

Robert Cherek, key account manager at D+H Polska, first heard about the plans for a science centre in Szczecin at the end of 2016. Shortly afterwards, he began working with the architectural firm Płaskowicki & Partnerzy:

"Our expert Tomasz Chilimoniuk from our Warsaw branch supported the designers and architects with the installation of our window and skylight drives", explains Cherek. "The NSHEV department at our headquarters in Wrocław then continuously adapted the drive selection proposals to the architects changing customer specifications."

D+H Polska came into contact with Przedsiębiorstwo Usług Specjalistycznych MVB for the detailed design of the automation solutions for the smoke extraction system.

Robert Cherek: "My team colleague Adam Mazur worked closely with their design department to optimise the product selection." After GOSCO was entrusted with the window work and skylight domes, they worked together on the solutions. "Maintaining the original technical parameters and functions was probably the most difficult moment in the entire process."

The offer presented at the end of 2020 was then "unrivalled" and was delivered on time by mid-2021. Cherek: "We then helped with the technical commissioning."

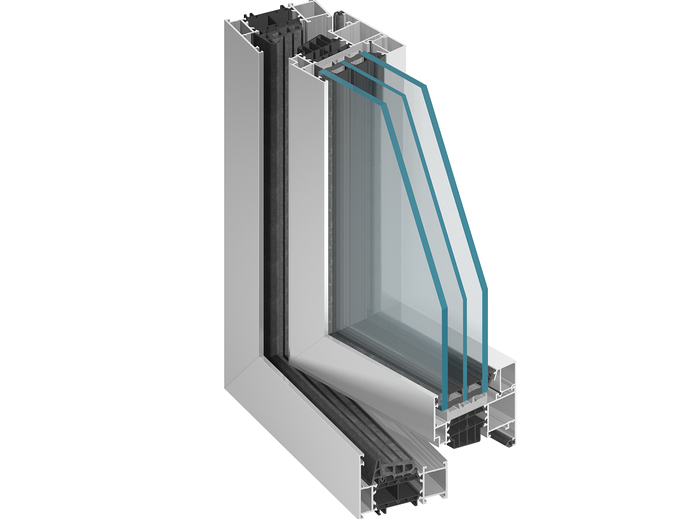

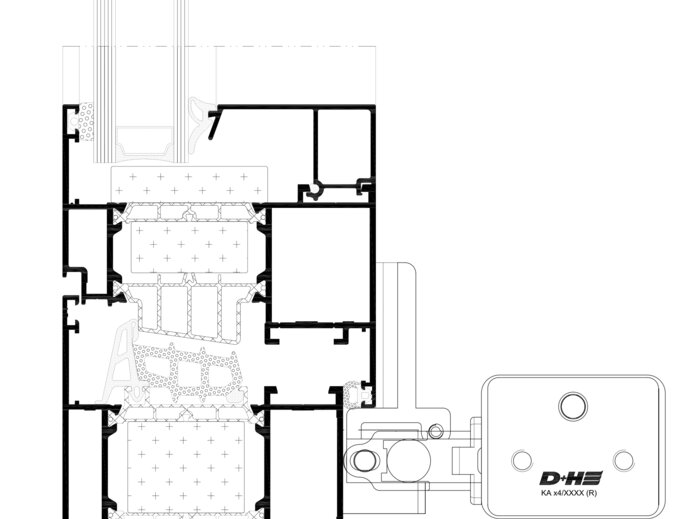

D+H Polska equipped the heavy double-sash roof windows for smoke extraction (1380*3790 mm) with DXD 300/1000-BSY+OT-HS rack and pinion drives. Vertical ventilation windows that can be tilted inwards are operated by KA 34/1000 series chain drives.

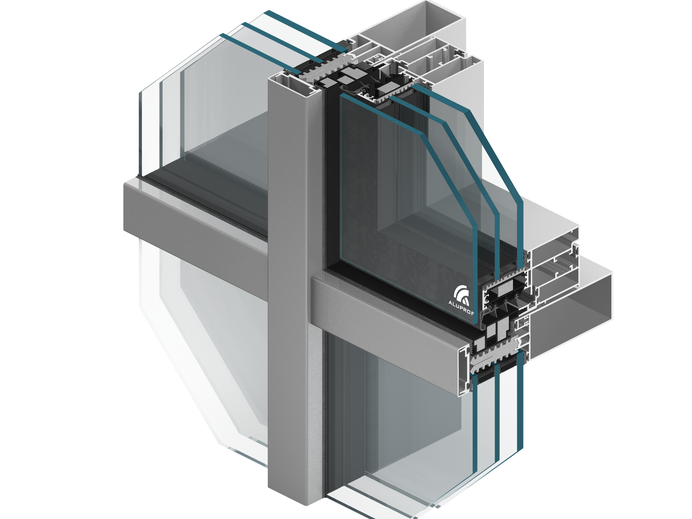

The windows were manufactured on Aluprof systems: The roof windows are based on the MBRW system and the façade windows on the MB-86 system.

RZN series control panels are in use: RZN 4364-E12 and RZN 4332-E6 slide-in control panels and RZN 4408-K compact control panels. These operations utilise the ACN (AdComNet) communication bus, which displays the status of the units and enables communication with the local BMS system via the modbus RTU protocol.

In addition, the attachment has a smoke and heat exhaust ventilation system based on the TSZ-200 control unit "The installation for the gravity-based smoke extraction system, which works with the mechanical air supply of the KL.2 stairwell, was realised using a smoke damper", explains Adam Mazur, an expert in working with designers and architects at D+H Polska.

A fan with a capacity of 10,000 m3/h supplies this zone with additional air. It is controlled and supplied with power via the TSZ-200 supply and control unit (equivalent to the MSE CPS-M control panel). Mazur: "It has an integrated interface for communication with the local BMS via the modbus RTU communication protocol. In addition to the status display of the operation, it is also possible to remotely fan the stairwell and open the smoke damper to discharge air or smoke via the roof."

An exhaust fan on the roof with a capacity of 50,000 cubic metres per hour per zone ensures smoke extraction on floor -1 and the restaurant on the ground floor. A duct system with flaps reliably removes smoke and reliably supplies air. The TSZ-200 supply and control unit provides the power supply and operation of the actuators.

In the entrance hall, the smoke is drawn in via smoke dampers (windows) in the skylight domes on the roof. Additional air flows in via automatically closing supply air windows on the ground floor and first floor as well as through doors. RZN series control units provide power and the operation of the drives. RZN control units utilise the AdComNet communication bus, which, in addition to the status display of the control units, also enables them to communicate with the local BMS system via the modbus RTU protocol.

"This special and technically demanding structure required an unconventional approach from the suppliers."

Mariusz Ziemecki, Managing director D+H Poland